I recently attended a great workshop on Design of Experiments (DOE). Now DOE has been around for a long time, and my ‘aha’ moment about the value of DOE for process improvement and understanding goes back to the early days of my career. But the workshop was a wake-up call as I realized how long it’s been since I’ve stress how important DOE is with a client. Continuous improvement can be approached in many different ways, but DOE can really help you not just improve your processes, it can also find the real sweet spots that lead to best process performance.

Now if you aren’t familiar with DOE, it’s a very powerful tool for process improvement. There are experimental designs that can help you understand which of your many process variables are most critical and other designs that can show you how the interaction between variables may be more important than any individual variables. And, the analysis can provide multi-dimensional response surfaces that can lead to new insights into how to run your processes. Here is a nerdy 2 minute YouTube video explanation of DOE. https://www.youtube.com/watch?v=-3ZBjmL_fME. It is a commercial.

The workshop, put on by Stat-Ease, featured their latest version of ‘Design Expert’ which is a powerful tool for designing and analyzing process experiments. This, and other software packages really make it easy to get deeper understanding of your process performance.

An experience like this workshop is a great incentive for taking a fresh look at the tools that are available for process improvement. It’s easy to get into a pattern of going to the familiar tools that have proven useful as of late, and letting some other tools go unused. DOE is a very powerful approach to process improvement and can be an important part of any continuous improvement program. I’m excited to think about where I can apply this to help clients with their process understanding, and it’s great to see that there are powerful software tools that can help make this happen.

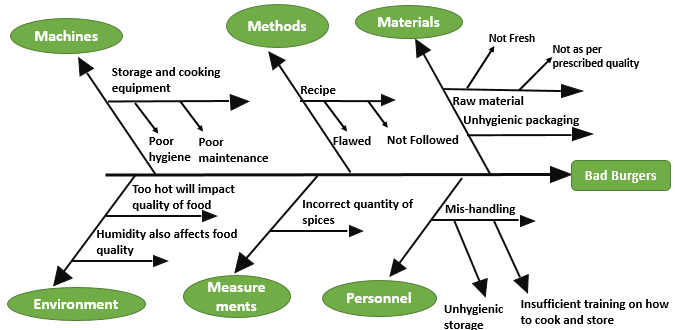

Design of experiments (DOE), at its core, is a systematic method used to find cause-and-effect relationships. So, as you are running a process, DOE determines how changes in the inputs to that process change the output.

https://www.statease.com/blog/category/beginner/

Leave A Comment